Welding & Fabrication with Pipeline Technology

Locations: Hermitage, Uniontown | 12-month Diploma

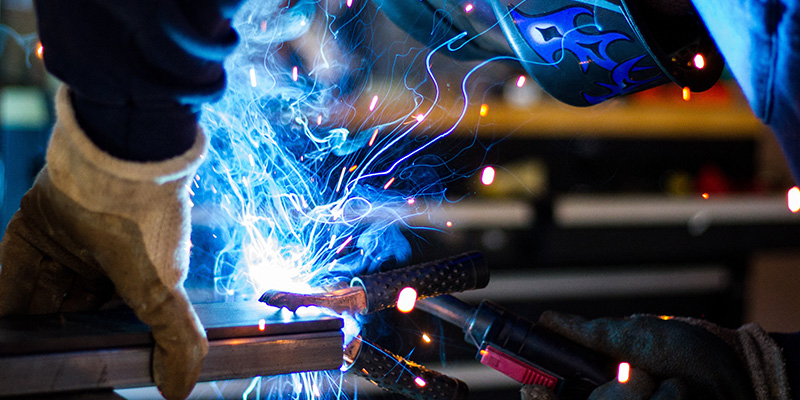

Laurel’s 12-month Welding & Fabrication program teaches practical and versatile skill that have a wide range of applications in numerous industries. Graduates have the opportunity to work with their hands, create tangible objects, and contribute to the world around them.

Skills Development:

Welding procedures

Blueprint reading

Fabrication

Layout

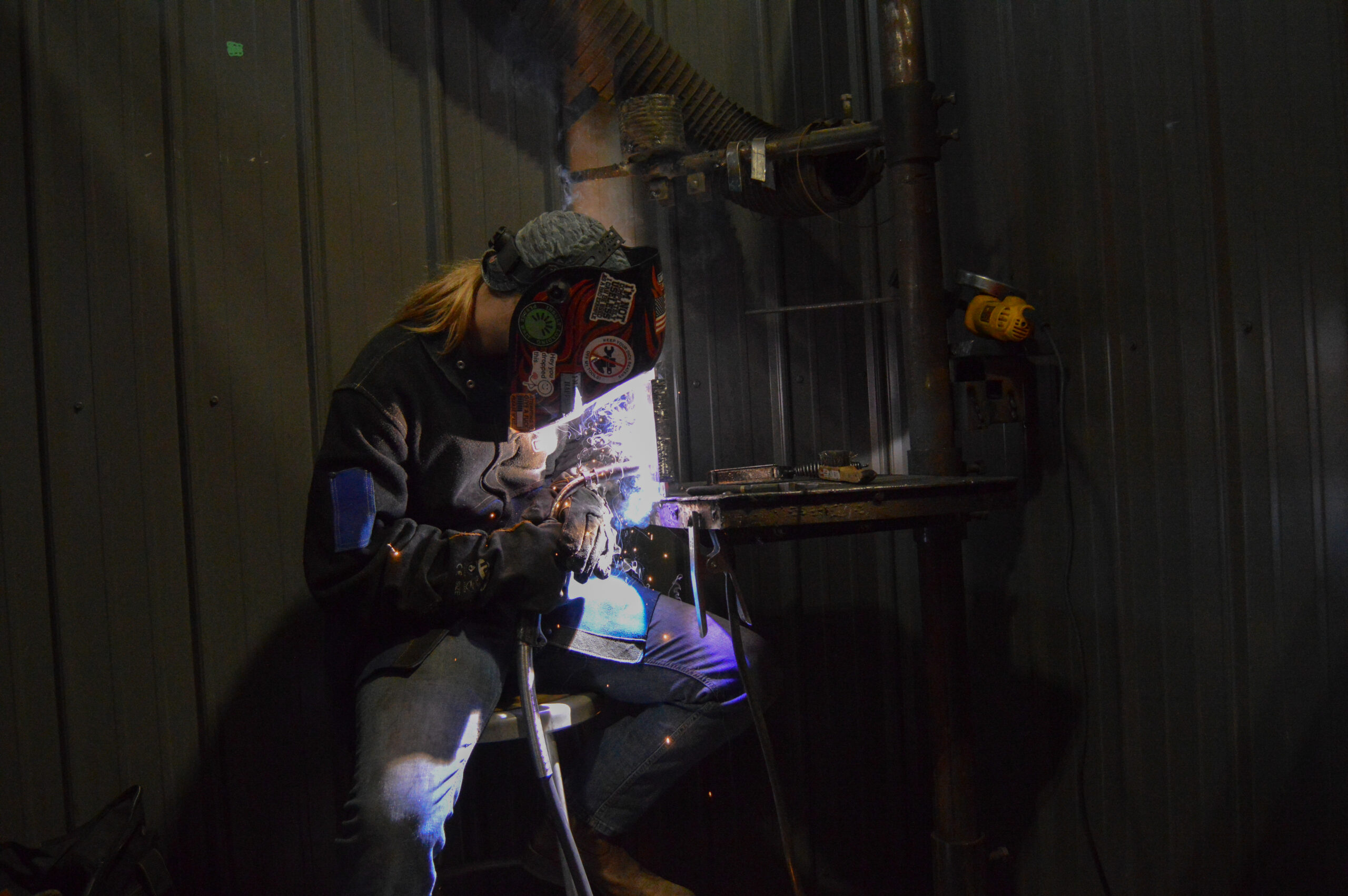

Laurel’s Welding & Fabrication with Pipeline Technology program will prepare graduates for entry-level positions in welding repair, welder fabricator, industrial mechanics, and pipefitter/welder. The curriculum provides students with a sound understanding of the science, technology and applications essential for successful employment in the welding and metal industry.

Additional instruction is provided in various processes and techniques of welding and fabrication skills. Coursework includes oxyacetylene welding, brazing, and cutting (OAW), Arc Welding (SMAW), MIG Welding (GMAW), Flux Cored Welding (FCAW), TIG welding (GTAW), Pipe welding and certification test preparation per current industry standards, practices and techniques. Courses in math and blueprint reading gives the student the industry-standard skills developed through classroom training and practical application.

Get Pipeline Specific Training

Pipeline welding is a specialized skill used in various industries, including aerospace, oil, construction, and auto manufacturing. Pipeline welders are responsible for installing and repairing pipes that transport substances such as water, chemicals and gases.

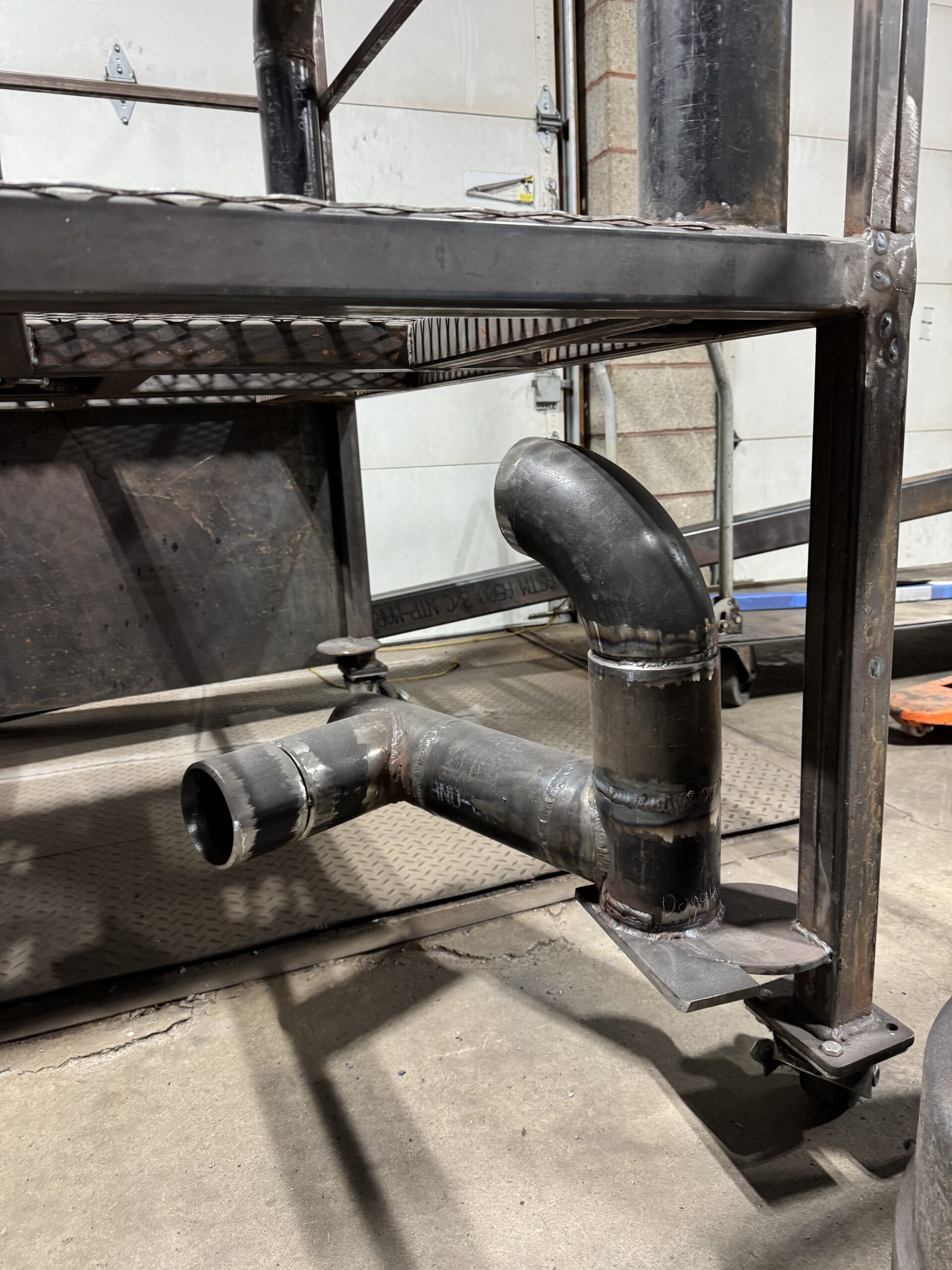

LTI has hands-on cirriculum dedicated to Pipe Welding and Pipeline Technology, so students can gain firsthand knowledge. Learn the different methods of welding pipes and tubes using different kinds of metal transfer, train in different positions used for pipe welding, along with the equipment needed for beveling and cutting joints during

the pipe welding process.

Certifications

Laurel’s program prepares you to take the following industry-recognized credentials:

Program Highlights

Learn various process of welding & fabrication

Hands-on experience in professionally equipped lab spaces

Prepare for industry standard certification through AWS

Content Courses

- Blueprint Reading

- Shielded Metal Arc Welding

- SMAW Pipe Welding

- Welding Inspection Techniques

- Gas Metal Arc Welding

- Flux Cored Arc Welding

- Gas Tungsten Arc Welding

- Layout & Fabrication

- Combination Pipe Welding

- Specialty Metals Welding

THIS LIST IS A SAMPLE OF COURSES. TO LEARN MORE ABOUT OUR COURSE OFFERINGS, FILL OUT THE FORM BELOW.

Request Information

Find out more about how Laurel can help get you started on your career path. Tell us a little about yourself!

Your Career Pathway

Occupation Outlook

Laurel encourages all prospective students to fully research employment opportunities when choosing a program of study. Please click the links below to learn more.

O*NET OnLine Occupation Search

Popular Occupations:

WELDERS, CUTTERS, AND WELDER FITTERS

PIPE FITTERS AND STEAMFITTERS

STEEL WORKERS

For a full program outline, see our school catalogs

Meet the Program Directors

Justin Caldwell

DIRECTOR OF TRADES

20+ years in Construction Trades

“The trades department at Laurel is one of the best. We have passionate instructors that put the students’ education first. We help people change their lives everyday.”